The Secret to a Stable Waterfront: A Guide to Choosing Dock Connectors

When planning or upgrading a dock system, most waterfront owners focus on dock sections, floats, or lift capacity. But one of the most important components is often overlooked—the dock connectors. These small but critical pieces of hardware are what hold your dock together, allowing it to remain stable, flexible, and safe in changing water and weather conditions.

In this guide, we’ll explain what dock connectors are, the different types available, and why choosing high-quality marine hardware is essential for long-term structural integrity.

What Are Dock Connectors?

Dock connectors are the hardware components that join dock sections together. They allow individual dock pieces to function as a unified system while still accommodating movement from waves, water level changes, and seasonal conditions.

Common dock connectors include:

-

Hinges

-

Pins

-

Brackets

-

Bolts and fastening systems

Without properly selected dock connectors, even the strongest dock materials can fail prematurely.

Why Dock Connectors Matter for Waterfront Stability

Dock connectors play a vital role in:

-

Maintaining dock alignment

-

Distributing weight and movement evenly

-

Allowing controlled flexibility

-

Preventing stress fractures and joint failure

High-quality dock connectors ensure your dock stays safe for people, boats, and equipment.

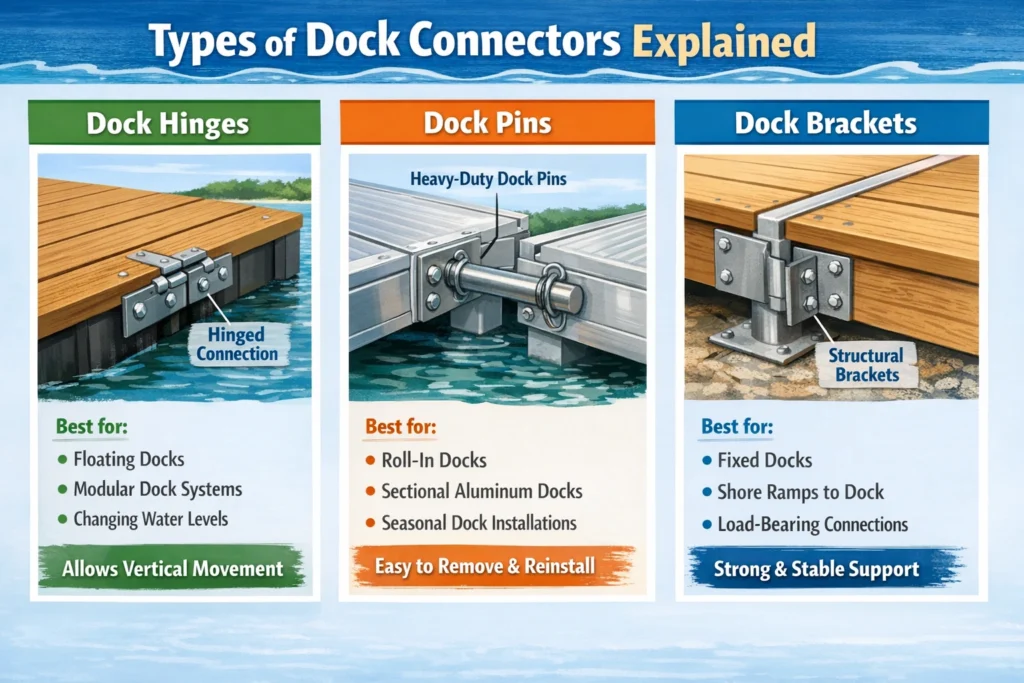

Types of Dock Connectors Explained

1. Dock Hinges

Dock hinges allow dock sections to move independently while staying connected.

Best for:

-

Floating docks

-

Modular dock systems

-

Waterfronts with changing water levels

Hinges reduce stress by allowing vertical movement instead of resisting it.

2. Dock Pins

Dock pins are heavy-duty fasteners used to secure sections together while still allowing limited movement.

Best for:

-

Roll-in docks

-

Sectional aluminum docks

-

Temporary or seasonal dock installations

Pins are often used where docks are removed and reinstalled seasonally.

3. Dock Brackets

Dock brackets provide structural support and help maintain proper spacing and alignment between dock sections.

Best for:

-

Fixed docks

-

Transition points (shore ramps to dock)

-

Load-bearing connections

Brackets are critical for stability and safety, especially in high-traffic areas.

Why Quality Marine Hardware Matters

It might be tempting to save money by using standard hardware from a big-box store, but “marine-grade” is a designation that exists for a reason. Here is why quality matters:

-

Corrosion Resistance: Fresh water and humidity can eat through standard steel in a single season. High-quality dock connectors are usually made from hot-dipped galvanized steel or marine-grade aluminum to prevent rust and structural failure.

-

Safety and Stability: Low-grade connectors can snap under the pressure of a heavy boat wake or a large group of people standing on the dock. Quality hardware ensures your platform remains level and secure under load.

-

Ease of Seasonal Maintenance: In Canada, many of us have to pull our docks out for the winter. Premium connectors are designed to be removed easily without seizing up, saving you hours of frustration during the autumn “pull-out” season.

Dock Connectors for Different Dock Types

Floating Docks

Floating docks are dynamic—they rise and fall with the tide or seasonal water changes. If you were to use a rigid connector on a floating dock, the constant upward pressure of the water against the weight of the dock would eventually cause the metal to fatigue and snap.

Roll-In Docks

Roll-in docks are the ultimate choice for areas with harsh winters where the dock must be removed to prevent ice damage. The priority for these connectors isn’t just stability; it’s speed of assembly and disassembly.

Fixed Docks

Because fixed (or stationary) docks are mounted on posts driven into the lakebed, they do not move with the water. This means the connectors must be able to withstand significant lateral (side-to-side) forces from wind and boat impacts.

Choosing the correct dock connectors ensures your dock system performs as designed.

Choosing the Right Connector for Your Shoreline

Choosing the right hardware depends on three main factors:

-

Water Movement: Is your lake calm, or are there frequent boat wakes and wind-driven waves?

-

Dock Type: Are you installing a floating, stationary, or roll-in dock?

-

Usage: Is this a high-traffic area for commercial use, or a quiet private swimming spot?

At Dockstop, we know that no two shorelines are exactly alike. We specialize in providing the heavy-duty dock connectors and hardware kits necessary to keep your investment safe and stable for years to come.

Complete Dock Systems and Hardware from DockStop

DockStop supplies complete dock and waterfront solutions, including high-quality dock connectors compatible with leading brands such as:

We also support installation, upgrades, and seasonal maintenance to ensure your dock hardware remains secure and safe.

Why Professional Guidance Matters

Incorrectly installed or mismatched dock connectors can lead to:

-

Unsafe movement

-

Structural stress

-

Premature wear

-

Increased repair costs

DockStop’s team can help assess your waterfront conditions and recommend the right connectors for your dock system.

The stability of your dock depends on more than just dock sections—it relies on the strength and quality of your dock connectors. Hinges, pins, and brackets work together to keep your dock safe, flexible, and structurally sound in changing conditions.

By choosing high-quality marine hardware and proper installation, you protect your investment and ensure safe waterfront access for years to come.

If you’re upgrading or building a dock system, DockStop is here to help you select the right dock connectors for your needs.